Understanding Pneumatic Ball Valves and Their Applications

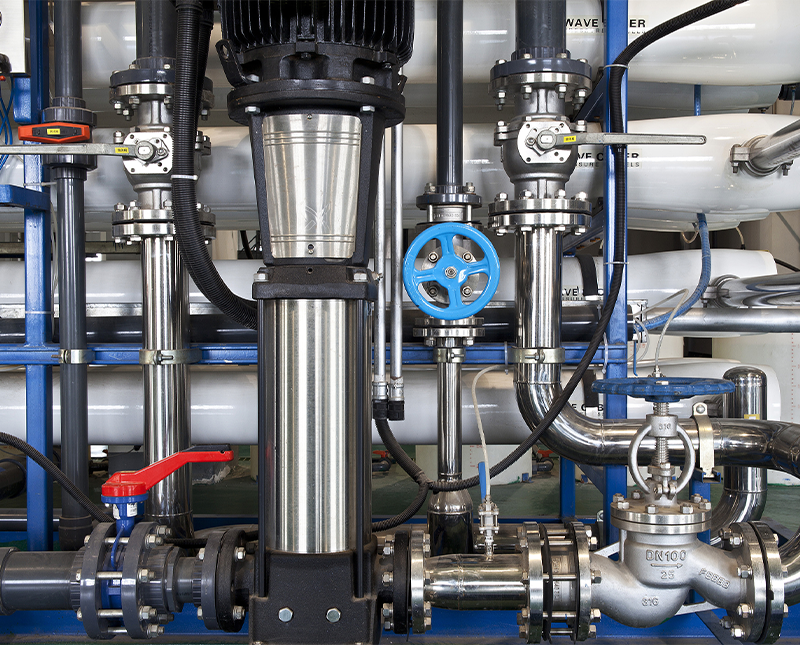

Pneumatic ball valves are essential components in modern industrial fluid control systems. Unlike manual valves, these valves are operated using compressed air, which allows for rapid and precise control of fluid flow. They are widely used in industries such as chemical processing, water treatment, food and beverage, and HVAC systems due to their reliability and automation capabilities.

A pneumatic ball valve consists of a spherical closure unit, known as a ball, which rotates to either allow or block the flow of liquids or gases. When paired with a pneumatic actuator, the valve can be opened or closed remotely, reducing manual intervention and improving operational efficiency.

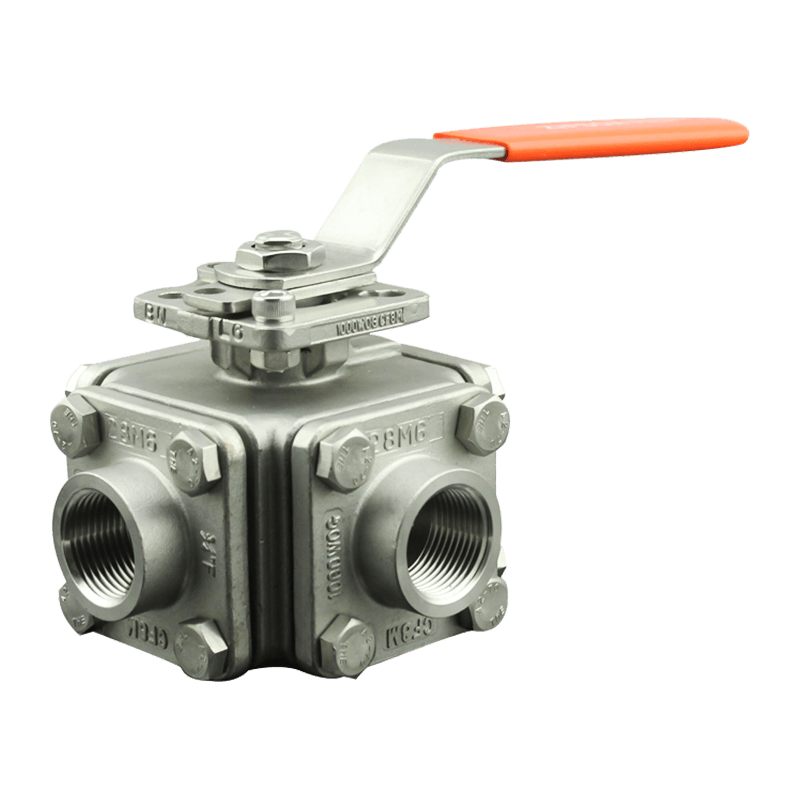

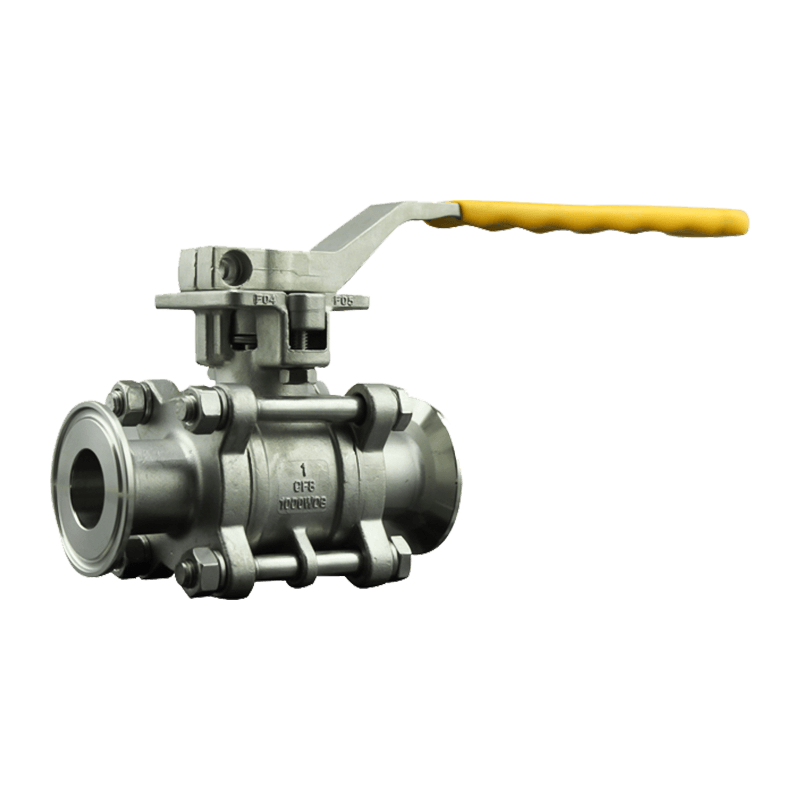

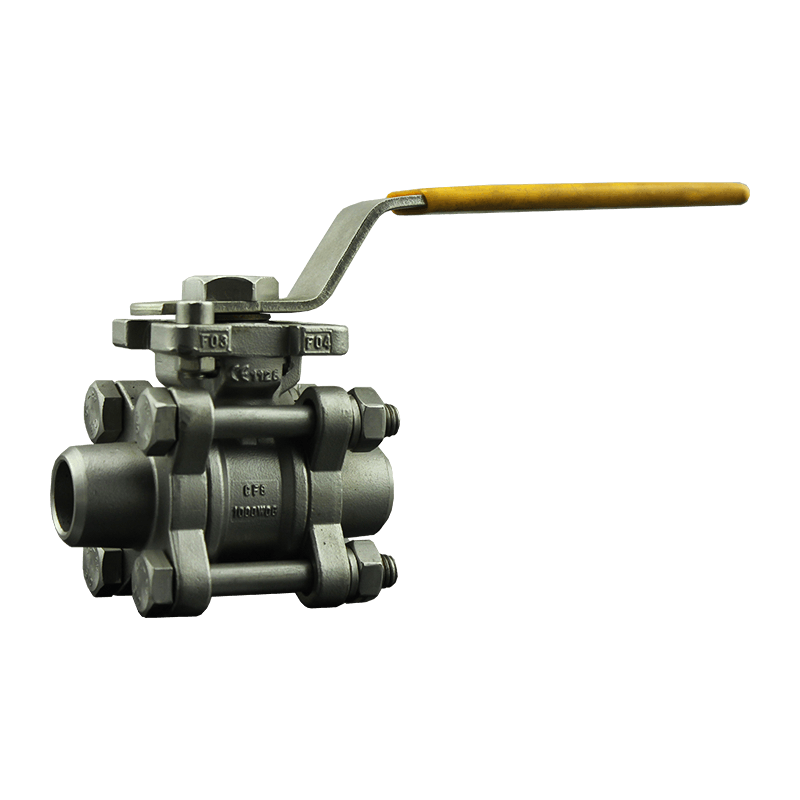

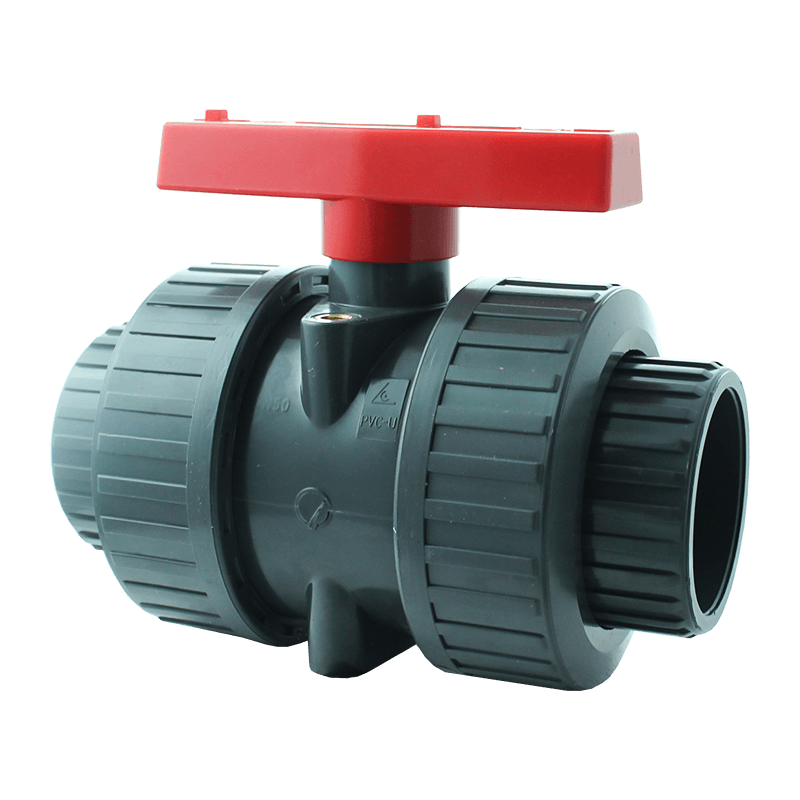

Types of Pneumatic Ball Valves

There are several types of pneumatic ball valves, each suited to specific applications. Selecting the correct type ensures optimal performance and longevity.

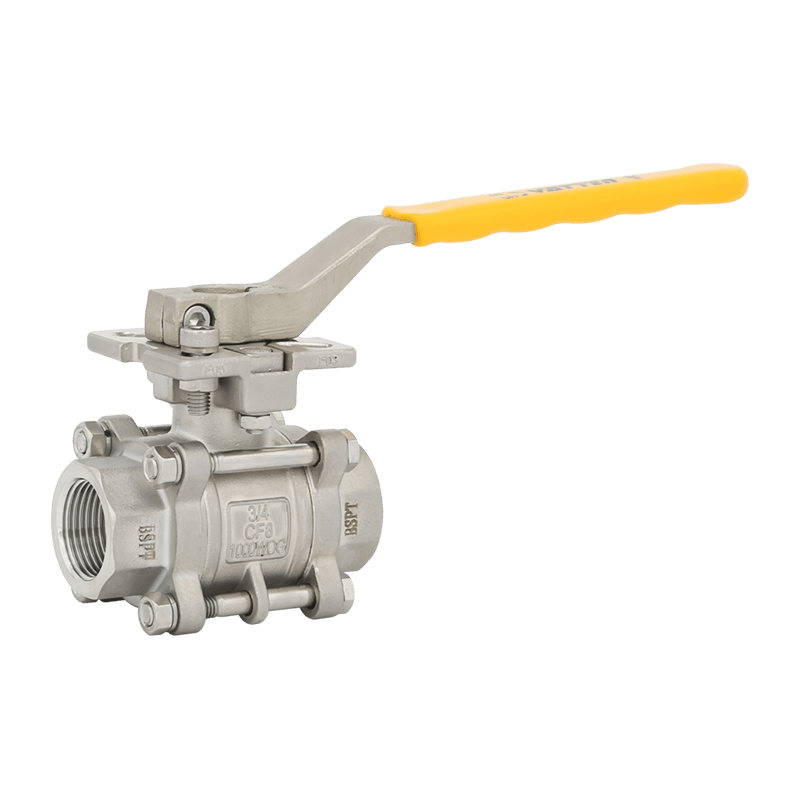

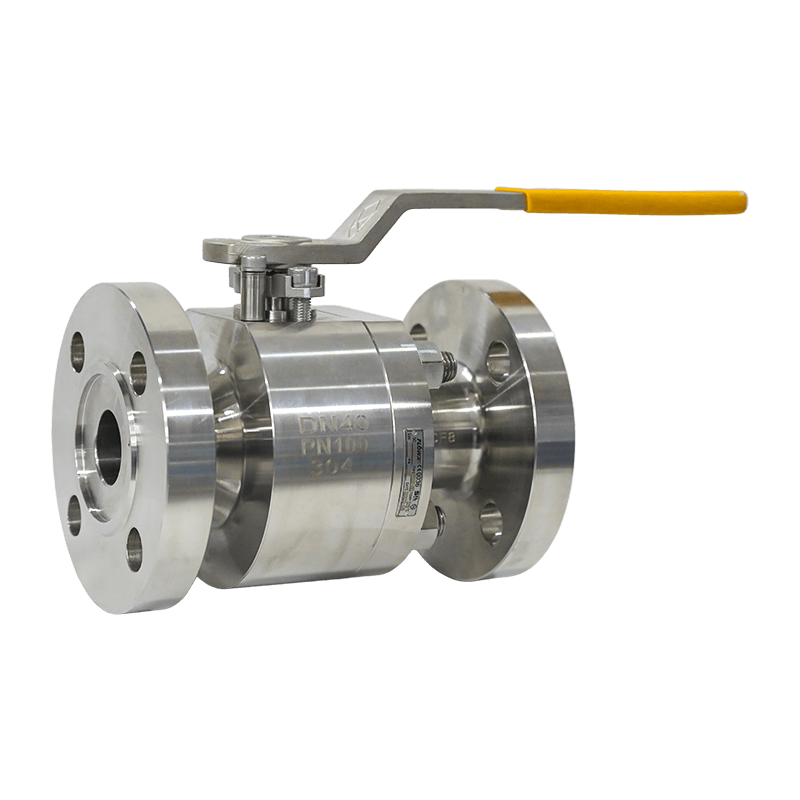

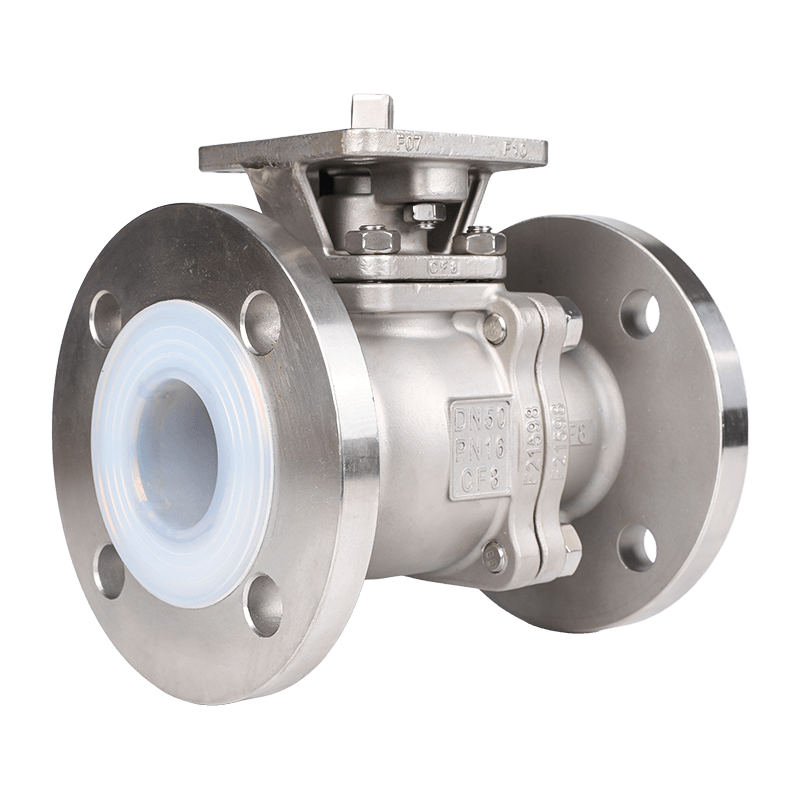

Two-Way Pneumatic Ball Valves

The most common type, two-way valves, feature one inlet and one outlet. They are ideal for simple on/off flow control. These valves are compact and can handle high pressure and temperature variations.

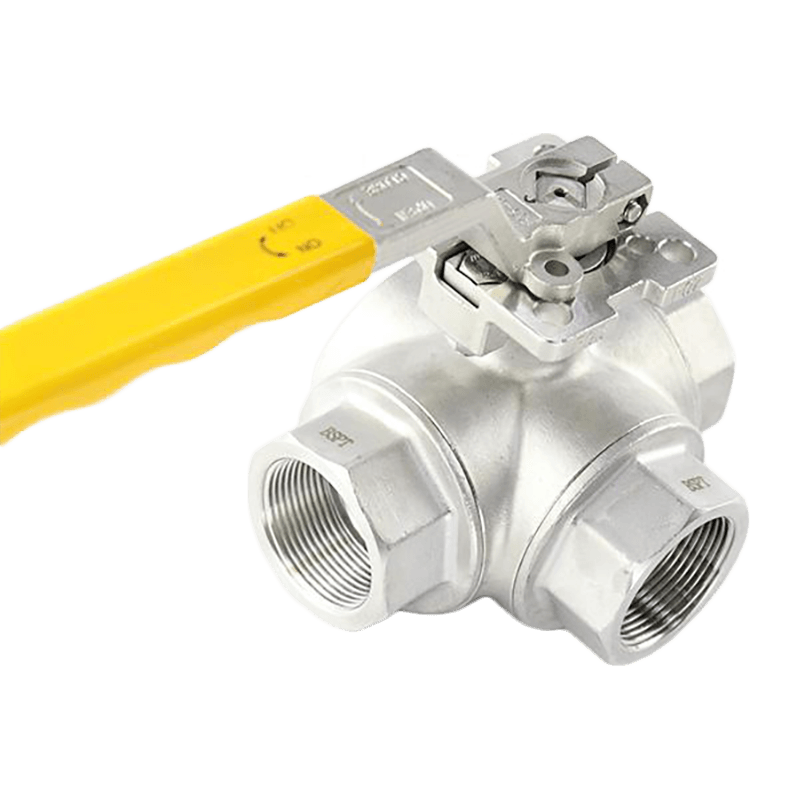

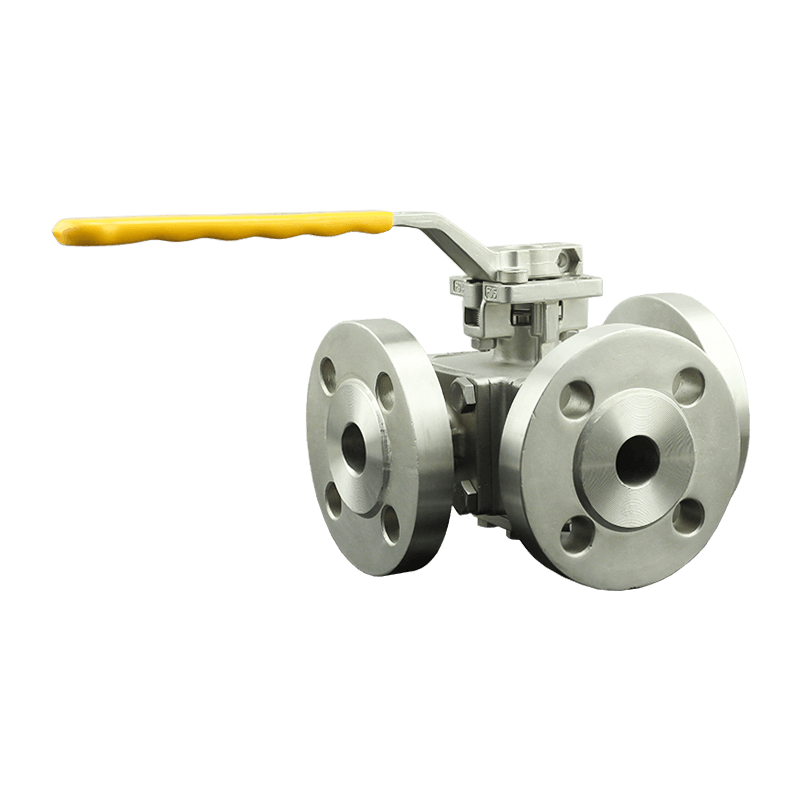

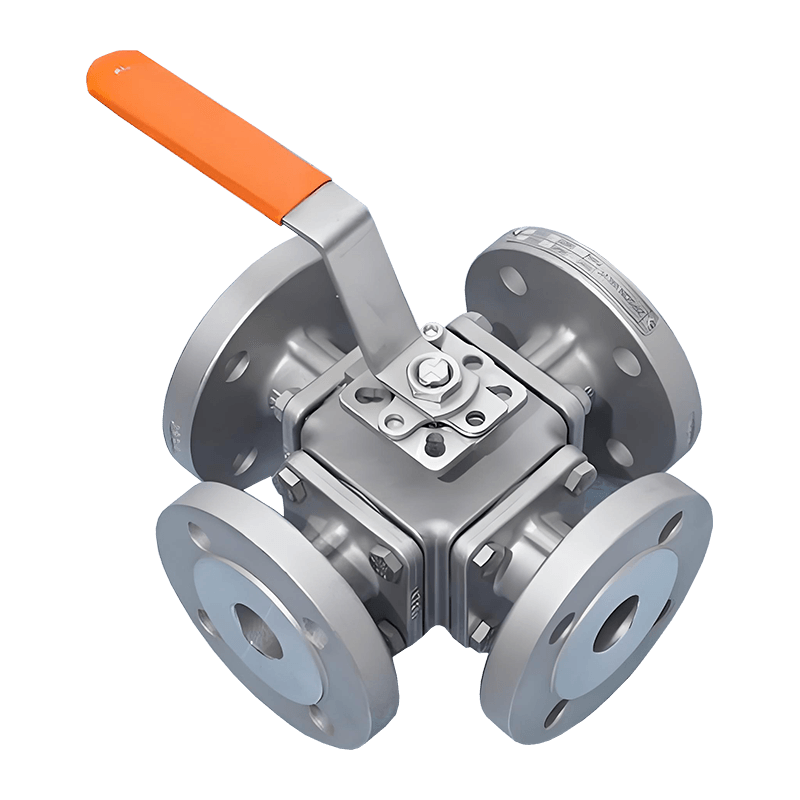

Three-Way Pneumatic Ball Valves

Three-way valves have one inlet and two outlets (or vice versa), allowing for flow diversion or mixing. They are commonly used in applications requiring fluid direction change, such as HVAC or chemical blending systems.

V-Port Pneumatic Ball Valves

V-port ball valves feature a V-shaped ball that provides better flow control and throttling capability. These are highly useful in applications requiring precise flow regulation rather than just on/off control.

Installation Best Practices

Proper installation of pneumatic ball valves ensures long-term reliability and avoids operational issues. Following these best practices will optimize valve performance:

- Check for compatibility between valve materials and the fluid type.

- Ensure that the pipeline is free of debris before installation.

- Align the valve properly with the pipeline to avoid stress on the actuator.

- Install isolation valves upstream and downstream for maintenance convenience.

- Verify the actuator is supplied with the correct air pressure and signal type.

Operation and Control of Pneumatic Ball Valves

Pneumatic ball valves operate using compressed air, which activates the internal actuator to rotate the valve ball. There are two main actuator types:

Single-Acting Actuators

These actuators use air pressure to open the valve and a spring to close it. Single-acting actuators are simple, reliable, and safe in power-loss situations since they fail to a predetermined position.

Double-Acting Actuators

Double-acting actuators use air pressure for both opening and closing. They provide faster operation and precise control but require continuous air supply for both movements.

Automated control can be integrated with PLCs or control panels, allowing remote monitoring and advanced process automation. Combining a pneumatic ball valve with positioners or solenoid valves improves response times and reduces human error in industrial systems.

Maintenance and Troubleshooting

Regular maintenance ensures pneumatic ball valves remain reliable and reduces downtime. Key steps include:

- Inspect the valve for leaks, corrosion, or wear on the ball and seat.

- Check actuator performance, including air supply and response time.

- Lubricate moving parts if required by manufacturer recommendations.

- Test the valve in both open and closed positions periodically.

Common troubleshooting issues include:

| Issue | Cause | Solution |

| Valve not opening | Insufficient air pressure | Check air supply and connections |

| Leakage at seat | Worn ball or seat | Replace ball and seat |

| Slow operation | Dirty actuator or piping | Clean actuator and pipelines |

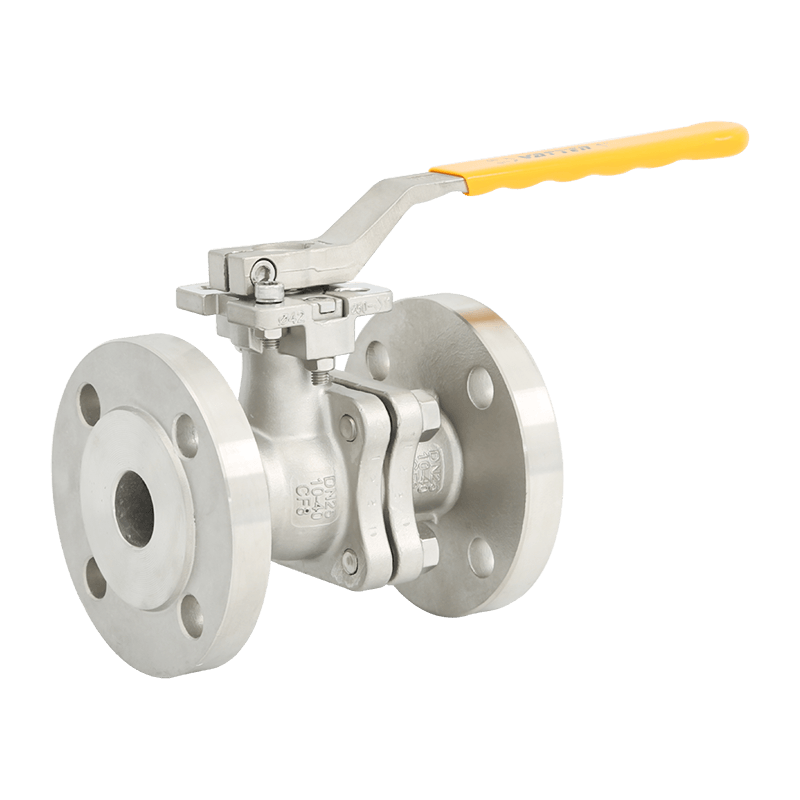

Selecting the Right Pneumatic Ball Valve for Your System

When selecting a pneumatic ball valve, consider the following factors to ensure optimal performance:

- Type of fluid (water, chemicals, gas) and its properties.

- Operating temperature and pressure requirements.

- Valve size and flow rate capacity.

- Actuation type and control method.

- Material compatibility for corrosion resistance and durability.

Choosing a valve that meets both technical requirements and industry standards ensures safe, reliable, and long-lasting operation.

Conclusion

Pneumatic ball valves are versatile and efficient solutions for automated fluid control in industrial systems. By understanding their types, installation procedures, operation mechanisms, and maintenance practices, operators can achieve reliable performance and extend valve lifespan. Proper selection and routine checks will minimize downtime, reduce maintenance costs, and improve overall system efficiency.